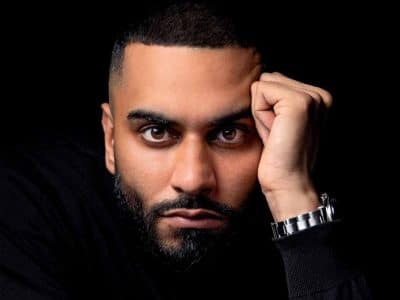

Last few years haven’t been an easy ride for Tetra Pak, its CEO reveals.

In the 1940s a young Swedish scientist invented the tetrahedral package. Erik Wallenburg was paid just £300 but his invention went on to become one of the most iconic products of all time; the Tetra Classic. Originally designed to transport milk, it wasn’t long before billions of cartons carrying everything from fruit juice to soup were being sold across the world.

More than 60 years later Tetra Pak’s expansion plans are just as ambitious. The firm plans to increase its market share by five percent year-on-year, the Middle East being one of its most crucial areas. “We are seeing 50 percent [growth] in the next ten years and the Middle East will share a big portion,” says Dennis Jönsson, Tetra Pak’s president and CEO. “The main areas of growth that we have identified are the greater Middle East, greater China, South East Asia, South America and Eastern Europe.”

Last year Tetra Pak, one of three groups that belong to the Swedish Tetra Laval Group, generated net sales of $10.7bn. Despite the global economic downturn, the firm saw better-than-expected sales in the fourth quarter, mainly as a result of greater stability in emerging markets. The same year the Swiss-based firm supplied around 145bn individual packages and delivered 70.7bn litres of milk, juices and other products to consumers.

In this day in age it wouldn’t be wrong to assume that Tetra Pak is a public company but it is in fact still owned by the Swedish family that started it more than 60 years ago. It was Dr. Ruben Rausing – the current owner’s grandfather – who first developed the idea for the carton, reportedly while watching his wife Elisabeth stuffing sausages, folding over and pressing shut the skins at each end. He wondered if he could develop a similar process for packaging liquids.

It was Rausing’s sons, Hans and Gad, who embarked on a global expansion drive, which saw the company grow from seven members of staff to one of Sweden’s largest corporations. By 1959, Tetra Pak’s production capacity had reached one billion cartons per year across eight countries. A year later they opened Tetra Pak’s first production plant outside of Sweden, in Mexico.

In 1979, Tetra Pak began its operations in China, which is today its largest market. In 2008, its Chinese operations generated ten percent of its overall business in terms of revenue. And yet, despite the size and importance of the country, it has been one of the toughest markets for the packaging company in recent years. Not only has it had to battle the downturn, it has also faced increased competition. In mid-2000 new players such as SIG, Elopak and Pure-Pak broke the firm’s 20-year monopoly on the market. This was further compounded by the melamine crisis several years ago.

In 2008, it emerged that melamine (a substance used in the manufacture of plastics) was cut into baby milk power to boost protein levels and increase the profits of dairy suppliers in the country. The case quickly became one of China’s worst ever food safely scandals, leaving six children dead and 300,000 sick.

But it wasn’t just powered milk that was affected. The chemical was also found in liquid milk, severely affecting Tetra Pak, which generates two-thirds of its business from packaging sales to dairy processors. While the scandal culminated in the execution of two people and the bankruptcy of state-owned Sanlu, milk sales declined by 50 percent. “Something like that hitting your biggest market is painful,” says Jönsson. “We saw the immediate impact; consumers just stopped buying milk,” he continues. “We ended the year with growth that originally looked like it was going to be spectacular to about five percent as a total.”

Although the crisis was initially confined to China, the ripple effect reached as far as New Zealand, the UK and the Middle East. While Qatar banned the import and sale of a popular Chinese sweet which was thought to be contaminated, Saudi Arabia’s Food and Drug Authority announced it had found harmful concentrations of melamine in milk powder. “Yes, [it did reach the Middle East]. In the beginning there was some concern about the impact it would have and it did heighten the awareness of this [but] we never saw an impact from a safety point of view,” says Jönsson. Despite some criticism concerning the speed at which Chinese authorities handled the situation, Jönsson is full of praise for his firm’s Chinese operations, which helped Tetra Pak recover quicker than expected.

“What our people in China did extremely well was work with the government on one side and customers on the other in order to, number one, ensure that it doesn’t happen again and number two, instill confidence in the consumers. It was really thanks to that we could see a recovery,” he says. “It took some nine months between falling 50 percent and seeing it back to the same volumes we had before. That was quick based on our initial expectations because our people thought it would take approximately two years.”

Despite the setbacks, Tetra Pak still sees continued growth in emerging markets, pledging millions of euros on new facilities in both China and Pakistan. In 2008, the firm invested around €90m ($110.5m) on a packaging material factory in Pakistan and in July opened a €60m plant in Hohhot, China, which manufactures around 11bn cartons. It is also planning to further expand its business in Iran.

The Middle East is also becoming increasingly important for the packaging firm. In the last three to four years the region has accounted for seven percent of its global sales, a figure which is growing at 15-20 percent. Jönsson has identified Tetra Pak Arabia, which covers Saudi Arabia and 24 other countries including Yemen, the UAE, Bahrain, Kuwait, Qatar and Oman, as an area of continued growth. Its partnership with the UAE-based Lacnor, which produces long life milk and juice, is particularly important. This year the two companies are celebrating 30 years of collaboration. “[The partnership] exemplifies a strong place today but more importantly a strong place in the world. It’s not only important to work with the large customers of today but also the ones that might become much more,” says Jönsson.

Continuing to grow during the recession isn’t Jönsson’s only priority, so is improving Tetra Pak’s green credentials. Although much of the firm’s success and growth is built on its sustainable qualities (unlike other forms of packaging Tetra Pak can be fully recycled) the company’s approach towards sustainability has been criticised on a number of occasions.

In 2004, the firm was dropped from 95+ – a group of companies run by the Worldwide Fund for Nature – due to ‘misleading’ adverts promoting its environmental credentials. Then in a 2007 article, the UK’s Guardian newspaper claimed that just seven percent of local authorities accepted Tetra Pak for recycling, compared to 65 percent of cartons being recycled in Germany and 30 percent in Europe. Jönsson says the newspaper’s claims took the firm by surprise. “We had to be reactive because it was something that became very public; it took us by surprise and we had to make heavy investments in recycling,” he explains. “Because the iconic packaging is made from cardboard as well as low-density polyethylene and aluminium foil, the recycling process is much more complicated than other forms of packaging which are made from one material,” he adds.

In 2007, the firm pledged £1.2m ($1.7m) to “help boost carton recycling rates” in the UK. “We invested in collection points – that was the most important thing,” he continues. “Right now we are ensuring that there is the technology behind it in order to separate the materials so that you really get the most value out of each one of these materials.” He adds that recycling rates, although improving, vary dramatically depending on the region. “In Germany we are seeing recycling rates of 70 [percent] plus while places like the US or China levels are still below ten percent,” he says. “We need to improve our recycling rates everywhere and we are taking a very strong view when it comes to our top tier market.” Yet another hurdle for Jönsson to successfully tackle.