Leading the GCC with a US$10 billion hospital-building

initiative, Saudi Arabia is certainly preparing for a sharp rise in demand,

while Kuwait has earmarked KD37 billion (US$127 billion) for hospital projects

in the next four years, with a view to replacing inadequate facilities built

three decades ago.

Along with a growing need for healthcare facilities, there

inevitably emerges a new demand for hospital building, and as with all

developing markets, it is critical to adopt an integrated approach from the

outset. WSP Middle East’s technical director for healthcare Carl Platt says:

“Healthcare facilities are far more complex in their design than other types of

projects. The entire construction team is liable for ensuring quality standards

are met, and there are far more opportunities to get it wrong if you do not

know what you are doing.”

But before firms can even think about the general risks of

hospital building, industry specialists urge them to consider the less obvious

complexities that make hospital construction so unique. “Hospital projects are

more technologically advanced than standard construction projects as they have

more intelligent systems built into them,” says Aldar Properties’ senior

development manager Hadi Sha.

“Due to the number and complexity of these systems, there is

typically a lot of infrastructure congestion which can create co-ordination

issues and slow construction down. Medical equipment, IT and security systems,

for example, are constantly being updated during the construction period, which

can mean last-minute modifications are required.”

Quality

At the same time, contractors and designers are expected to

ensure a certain standard of quality. “Minimising the changes to the project

can help prevent a number of issues, but it is part of the industry’s DNA to

continuously seek new and innovative methods of delivering healthcare

facilities without compromising on overall quality.”

Intensifying difficulties is the fact that the UAE has no

specified healthcare standards, but tends to adopt US policies and Health

Technical Memorandums (HTMs) from the UK when required. Meanwhile, the

projects continue to be subject to government and local health authority

requirements, which vary according to the individual project and regional

demand, as well as an array of conflicting departmental specifications.

“Each hospital department has a different set of end user

requirements,” says Meinhardt’s hospital expert and head of MEP division

Stephen Clough. “In some projects you can deal with as many as 20 different

departments, so co-ordinating needs can be challenging. Often they each wish to

impart their own set of requirements which may be contrary to the agreed

general standards.” Referring to a trend of tight programmes and detailed

design specifications, Clough says that collating comments and approvals from

hospital operators can be a lengthy process. “Budget can also be an issue as

additional requirements by the end user can have a significant effect on

costs.”

One hospital feature that is particularly dependent on good

design is the need for privacy, though the requirements will vary according to

the type of hospital and location of the project. In Saudi Arabia for instance,

it is necessary to separate ladies’ and men’s sections when designing the unit,

while the number of rooms and services of any facility may be affected by the

unit’s medical specialty and average length of in-patients’ stay. The amount

and size of equipment will also need to be considered.

Space planning

As regards upholding patient dignity and care, space

planning is essential. “It can be difficult, but it is nonetheless critical to

ensure adjacencies between departments for the sake of patient dignity,” says

Platt. “For example, diagnostic and imaging suites should be positioned close

to accident and emergency departments.” Designers also need to take special

care at the design stage to avoid patients being wheeled around

highly-populated areas on trolleys or in hospital clothing.

Designing the building in such as a way so as to eliminate

the spread of noise through a facility is also important, which means MEP has

to take acoustic control into account, through strategies like fitting

attenuators in air ducts to limit sound travel. Perhaps more widely

acknowledged than the design complexities are the extremely specific MEP

requirements of hospital projects – central to efficient operation due to the

need for a closely-controlled, infection-free, safe environment, impervious to

electrical failure.

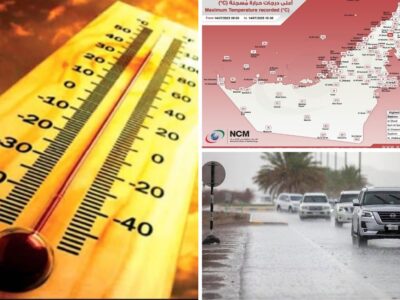

The unique challenges, which largely revolve around thermal

control, air management, power generation, waste disposal and equipment

installation, not only impact on the MEP contractor, but on all parties

involved in the project’s design and construction.

Unlike the UK

where thermal control is about keeping hospitals warm, in the UAE there is a

clear need to keep the facility cool. Contrary to standard projects where

sustainable air-con systems are installed simply and easily, hospital cooling

is more complex. Burdened with having to balance the demand for cold air with

that for natural light, hospitals are under pressure to reduce the amount of

energy used by cooling systems whilst preventing the spread of airborne

diseases – a difficult task given that most sustainable air-con systems rely on

re-circulated air.

Solar gain

Platt explains: “One of the challenges of hospital building

in the GCC is to reduce the large solar gains into the hospital. The use of

glazing to provide natural light (proven to be beneficial in the healing

process) can be problematic when you imagine what the inside of a car is like

in the summer. But, of course, we do not want to simply install bigger

chillers, due to the large amount of energy they consume.

“To maintain thermal control, engineers need to consider

alternative options such as greater insulation to keep warm air out, and

shading options which can limit the solar gains by the fabric of the building.

The difficulty with recirculated air is that you risk spreading infection. In a

normal building you would literally just recirculate the air, but in a

hospital, and especially in areas such as operating theatres and intensive care

units, this is not possible, as you would be recirculating contaminated air.” A

more efficient system is to pump filtered fresh air into a room, pull the air

out and just cool it down with the existing air.

Containing airborne diseases generally in areas of risk such

as operating theatres and intensive care units is also complicated by the need

to maintain positive air pressure in order to protect patients. “The mechanical

systems in a hospital are very advanced; the MEP works specifically have a

higher and tighter specification in a hospital than on other projects, and

there is more emphasis on air filtration,” says Clough. “Services are designed

in such a way as to compartmentalise areas to prevent the spread of airborne

diseases, and the pressurisation arrangement has to be carefully considered.”

Infection is also spread through waste. Platt says waste

disposal is a major consideration for designers and contractors, with different

systems having to be installed for different types of waste. “There are three

types of waste in hospitals, one is the general waste from sinks and toilets,

another is the chemical waste from laboratories and the last is the waste from

cleaning and sterilisation. Each type of waste must be managed separately so as

not to enter the water system and spread infection. This creates additional

challenges for construction firms and MEP specialists, who respectively have to

design and implement these systems.”

Finishing works

The finishing works, sometimes perceived to be

‘post-construction works’, are extremely important in hospital building.

According to technical experts, the need for perfection puts a substantial

amount of pressure on those not only carrying out the finishes, but on the other

contractors as well. “Upon completion, a hospital building has to be

immaculately clean,” explains Clough. “This means that nothing other than the

equipment required should be left in floor or ceiling voids, dust has to be

kept to a minimum during all stages of the build and surfaces have to be

sealed.”

Central to these requirements is hygiene and the ongoing use

of the building after construction – it being imperative to consider the

long-term operation of the facility during the design, supply and construction

phases. The paints and all the finishes must be washable and must not allow

bacterial growth. All the materials and equipment installed must be suitable

for their purpose for a long time without the need for regular repair and

maintenance. In a hospital, you cannot tolerate failures or shutdowns for

repairs.