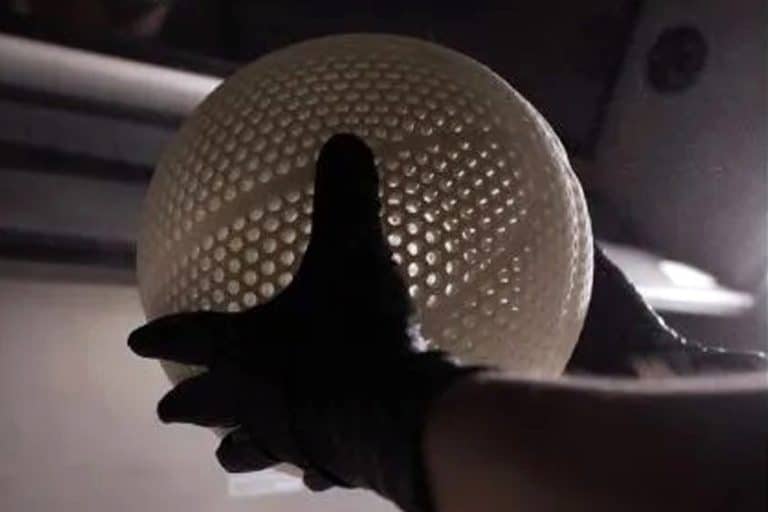

The world’s first 3D-printed airless basketball has been released in a new technological advancement by Wilson, the American sporting goods company and manufacturer of professional level basketballs.

The Wilson Airless Prototype eliminates the need to inflate the ball and relies on a 3D-printed structure and research grade materials that can replicate the bounce of a traditional basketball.

The surface of the ball consists of small hexagonal holes that allows air to flow through easily, with eight panel like lobes, the basketball is set to revolutionize the sport.

The airless basketball was designed by the team behind the official NBA game basketball.

The ball prototype after being printed was sent to the NBA facility in Ohio where it went through rigorous testing.

“This is only a dot on the development path but we’re really excited about the first step that we have here. That’s our goal, that’s our job, to push boundaries and change perceptions of the brands,” said Kevin Krysiak, Senior Director of R&D and Innovation – Basketball at Wilson Sporting Goods.

The 3D-printed ball can be dyed in various colours. A black prototype was released during the 2023 NBA All-Star weekend.